Featured Products

-

Supply OEM Crankshaft Power Steering Double Lip Metal Oil Seal Rings Assy Axle Duo Cone Mechanical Face Floating Seal

Easy to install: Designed to precise requirements and manufactured to tight tolerances, they will not come off after fitting

Cost reduction: Within a certain limit of clearance, the O-ring will make an effective seal. The use of retaining rings expands the clearance limit and allows loose assembly of moving parts.

There is a shape to obtain better performance: the design of the profile (regardless of the form of installation) ensures improved performance.

Low price: compared to other types of retaining rings, our retaining rings are less expensive

Extends the working life of O-Rings

Improved lubrication

High pressure resistance -

Manufactur standard M74D-95mm/G9 Mechanical Seals Double Face Dual Seal for Chemical Pumps (Material: SIC/SIC/SIC/VIT Or TC/TC/TC/VIT)

The M2 type seal is a reciprocating seal that can be used for both external and internal circumferential sealing, and is suitable for harsh conditions and special media.

Can be used for reciprocating and rotating movements

Adaptable to most liquids and chemicals

Low coefficient of friction

No crawling even with precise control

High corrosion resistance and dimensional stability

Withstands rapid temperature changes

No contamination of food and pharmaceutical fluids

Can be sterilized

Unlimited storage period -

Factory directly M74D-35mm Mechanical Pump Seal M74D Mechanical Double Face Seals for Chemical Pump

Outer edge of oil seal: rubber covered, seal lip short and soft, with spring, dust-proof lip.

This type of Oil Seals is mainly used in situations where there is Oil and pressure, and the skeleton of Oil Seals TCV is a whole structure, so the deformation of the lip under pressure is small, and it is suitable for use in situations where the axial diameter is large and the pressure is high (up to 0.89mpa). -

OEM/ODM Factory Single Face 560A Series Water Pump Mechanical Seal Rubber Mechanical Seals

The four lobed design provides twice the sealing surface of a standard O-RING.

Because of the double-sealing action,less squeeze is required to maintain an effective seal.The reduction in squeeze means less friction and wear which will increase service life and reduce maintenance costs.

Very good sealing efficiency. Due to an improved pressure profile over the X-Ring cross-section, a high sealing effect is achieved. -

Chinese Professional Mass Production of Sic Silicon Carbide Mechanical Seal Rings for Pump Industry

The M2 type seal is a reciprocating seal that can be used for both external and internal circumferential sealing, and is suitable for harsh conditions and special media.

Can be used for reciprocating and rotating movements

Adaptable to most liquids and chemicals

Low coefficient of friction

No crawling even with precise control

High corrosion resistance and dimensional stability

Withstands rapid temperature changes

No contamination of food and pharmaceutical fluids

Can be sterilized

Unlimited storage period -

2019 China New Design Silicon Carbide Mechanical Seal Rings for Pump Industry

Two functions – sealed and dust-proof all in one.

Minimum space requirements meet safe availability and ideal profile finish.

Simple structure, efficient manufacturing technology.

The EM type piston rod seal/dust ring can also be used in dry/oil-free air after initial lubrication due to the special geometry of the seal and dust lip plus the special material.

Due to functional lip optimization adjustment use its smooth running.

As the components are composed of a single polymer material, there is no corrosion. -

Quoted price for Silicon Carbide Pump Mechanical Seal Ring

Short installation length

Small starting friction, no crawling phenomenon, even at low speed can ensure constant motion.

Low friction losses

crushing

High temperature resistant -

Hot sale Luxmif PTFE Bellow Single Face Mechanical Seal 152 for Chemical Pump

V-ring VA is a unique all-rubber seal for rotation. V-ring VA is a very good seal to prevent the invasion of dirt, dust, water or a combination of these media, while absolutely retaining grease, because of its unique design and performance, V-ring VA can be used for a wide range of various types of bearings, it can also be used as a second seal to protect the main seal.

-

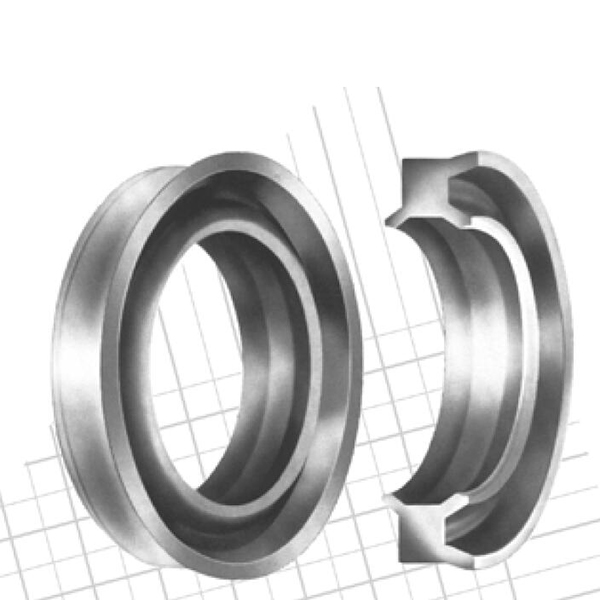

IOS Certificate Double Face Mechanical Seals Type 92b Mechanical Seal for Chemical or Lkh Pump

Mechanical end seals or heavy-duty seals are designed for rotary applications in extremely harsh environments where they can withstand very severe wear and prevent entry of abrasive external media. Mechanical end seals are known as heavy-duty seals, end seals, floating seals, life seals, Toric seals, and multi-cone seals.

-

Discount wholesale Atmospheric Sintering Sic/Ssic mechanical Seal Stationary Face Ring with High-Accuracy

This seal pack is used for harsh and harsh operating conditions. Currently mainly used

In order to meet the needs of providing maintenance spare parts for old equipment.

V-type sealing group EK type,

The EKV can be used for pistons with pressure on one side, or

A “back to back” installation is used for sealing systems with pressure on both sides of the piston.

• Able to withstand extremely harsh conditions

- Long service life

• Can be optimized to adapt to the use of the corresponding equipment

• Even if the surface quality is poor, it can meet the sealing requirements for a period of time

• Not sensitive to contamination of hydraulic media

• There may be occasional leakage under certain conditions for structural design reasons

Occurrence of leakage or friction. -

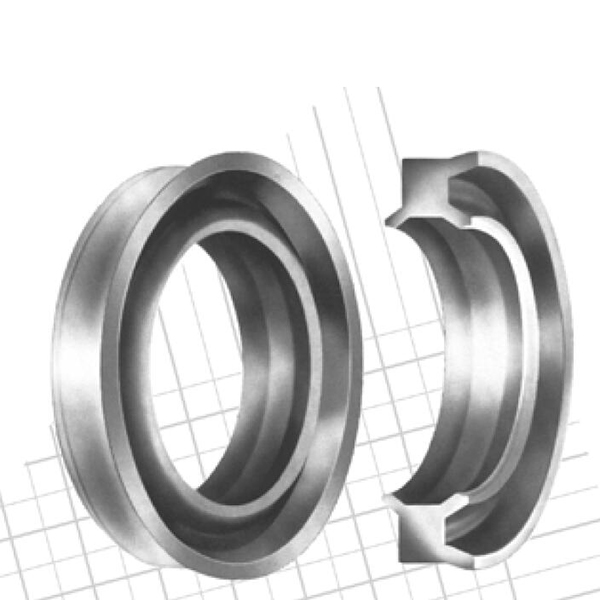

OEM/ODM Manufacturer Diameter Mechanical Sealing Ssic Face Seal Ring

Easy to install: Designed to precise requirements and manufactured to tight tolerances, they will not come off after fitting

Cost reduction: Within a certain limit of clearance, the O-ring will make an effective seal. The use of retaining rings expands the clearance limit and allows loose assembly of moving parts.

There is a shape to obtain better performance: the design of the profile (regardless of the form of installation) ensures improved performance.

Low price: compared to other types of retaining rings, our retaining rings are less expensive

Extends the working life of O-Rings

Improved lubrication

High pressure resistance -

OEM/ODM Manufacturer Diameter Mechanical Sealing Ssic Face Seal Ring

Easy to install: Designed to precise requirements and manufactured to tight tolerances, they will not come off after fitting

Cost reduction: Within a certain limit of clearance, the O-ring will make an effective seal. The use of retaining rings expands the clearance limit and allows loose assembly of moving parts.

There is a shape to obtain better performance: the design of the profile (regardless of the form of installation) ensures improved performance.

Low price: compared to other types of retaining rings, our retaining rings are less expensive

Extends the working life of O-Rings

Improved lubrication

High pressure resistance