High definition Piston O Ring - High quality O-ring seals manufacturer – Yimai

High definition Piston O Ring - High quality O-ring seals manufacturer – Yimai Detail:

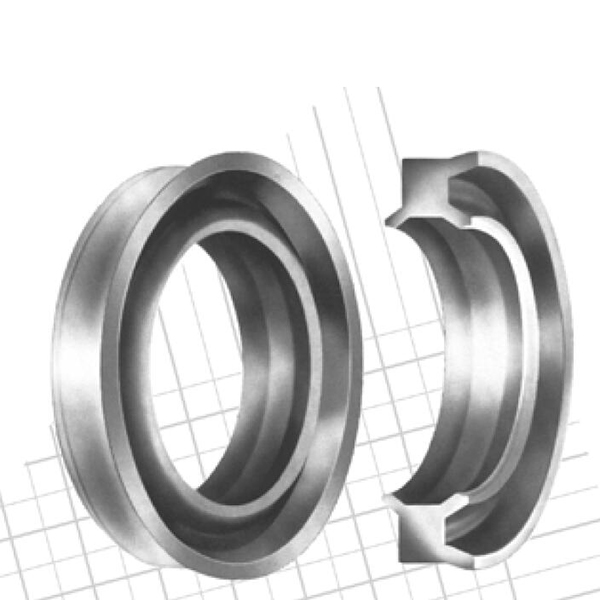

TECHNICAL DRAWING

The perfect O-Ring for each purpose

Our O-Rings are both cost-effective and perform highly in almost every environment. No matter if you need metric or inch, standard or custom-made O-Rings – any size of O-Ring seals is available – including giant O-Rings using our process. Our rubber O-Rings are made of EPDM, FKM, NBR, HNBR, as well as our proprietary FFKM. Special products apart from rubber O-Rings such as O-Rings in PTFE material and metal O-Rings are also available.

O-Ring Seals

O-Rings are used in a variety of fields: they are either used as sealing elements or as energizing elements for hydraulic slipper seals and wipers. Thus, the O-Ring is basically used in every field of industry including aerospace, automotive or general engineering.

The selection method of O-ring:

O-ring section is O-shaped (circular) ring seal ring, generally installed in the groove, using the right amount of compression to seal oil, water, air, gas and other fluids. The use of O-ring is static and movement of two types, if the use of conditions are not appropriate will occur fracture, swelling, cracking, etc. In order to maintain the sealing performance for a long time, it is necessary to select the suitable material and size of O-ring products.

O-ring seal is to prevent the loss of liquid and gas, the seal is composed of O-ring and metal groove, O-ring is made of rubber material, with a circular section of the ring, usually made of metal groove for placing O-ring, Ogae ring seal for liquid and gas is characterized by no leakage. This “seamless” can be achieved in a number of ways: O-ring seals are welded, tinned, brazed, surfacing bonded or partially or completely placed between two harder components of a softer material. Rubber or other plastic materials may be considered to be a viscous fluid with a high surface stress, incompressible, and sealed due to the O-ring’s anti-elasticity to compression and system pressure.

Advantages of O-rings:

1, can be applied to a wide range of pressure, temperature and clearance occasions.

2, easy maintenance, not easy to damage or pull tight.

3, there is no critical moment in the tension, will not cause structural damage.

4. O-rings usually require small space and light weight.

5, in many cases, O-rings can be reused, which is an advantage that many inelastic flat seals do not have.

6, under the correct use conditions, the life can reach the aging period of O-ring material.

7, O-ring failure is generally gradual, and easy to judge. ‘

8, although different amounts of compression will produce different sealing effects, but because it allows metal-to-metal contact, it will not have an impact on the O-ring.

9.It has a very low price.

O-ring material

When selecting O-ring materials, the main factors such as the medium, pressure and temperature range to be sealed should be considered in many aspects. A material may be best suited to steam, but in a water-cooling system will have negative effects due to alcohol or antifreeze additives, a material may be compatible with liquid oxygen at low temperatures, but completely unsuitable at high temperatures. O bezel material selection must be based on the specific application, O-ring sealing involves many factors, the final material selection should be the most comprehensive choice.

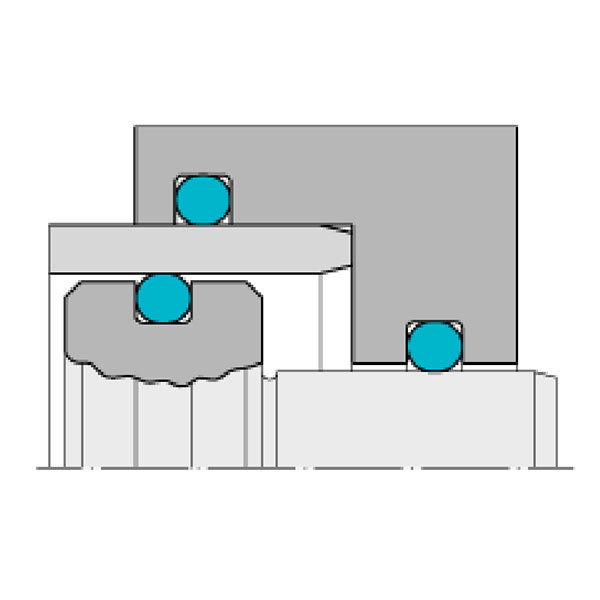

Static seal

Static seal is a seal in which two adjacent surfaces do not move relative to each other. Static seals are commonly found at the lower part of the bolt or rivet, at the joint joint, or at the bottom of the cover plate or faucet. It can be said that the O-ring is the best static seal since its development. The reason for this is mainly because the O-ring is a “fool seal”, which does not need to add tension when the original or over-pulled, and human error factors can not be ignored when ensuring the correct use of the O-ring. O-rings do not require large loads to achieve a zero-leak seal.

Dynamic seal

Dynamic seal refers to the reciprocating movement between the sealed parts, and the O-ring is displaced due to the existence of movement. In the hydraulic cylinder, O-rings can be used for piston or piston rod dynamic seal, especially suitable for piston or piston rod dynamic seal, especially suitable for short stroke, small diameter cylinder, countless O-rings have been successfully used in liquid, fluid, and even in the compressed air dynamic seal, in many cases, O-rings are used for long stroke, large diameter cylinder, if used correctly, The life of the O-ring can be the same as the life of the sealed component, the factors affecting the dynamic seal are extrusion, reciprocation, surface roughness and material hardness, in the design process, it is very important to consider these factors.

![]()

DoubleActing

![]()

Helix

![]()

Oscillating

![]()

Reciprocating

![]()

Rotary

![]()

SingleActing

![]()

Static

| Ø – Range | Pressure Range | Temp Range | Velocity |

| 0~10000 | ≤100 bar | -55~+260℃ | 0 |

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for High definition Piston O Ring - High quality O-ring seals manufacturer – Yimai , The product will supply to all over the world, such as: Yemen, Rome, Turkmenistan, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.