For some mechanical equipment with high sealing requirements, basically need to use such seals as mechanical seals, the reason why it can play a good sealing effect, mainly has a certain relationship with its structure, so in order to achieve a good sealing effect, we should have a deep understanding of its structure.

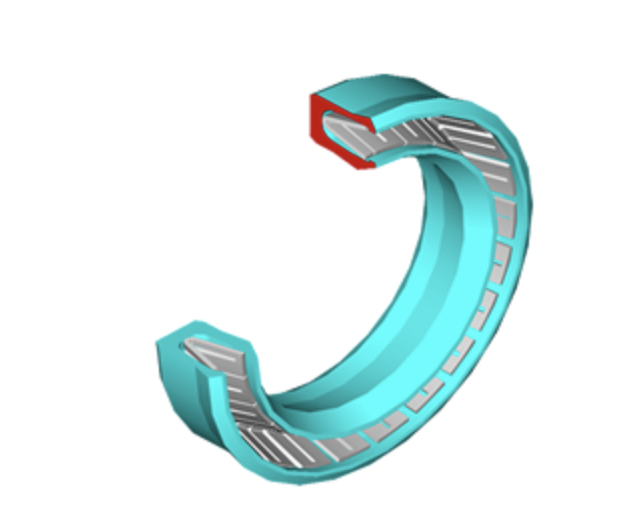

1. A sealing end face composed of a compensating ring and a non-compensating ring. Includes: dynamic ring, static ring, cooling device and compression spring. The end face of the dynamic ring and the static ring are fitted together to form the seal end face, which is the main component of the mechanical seal and plays the role of the main seal, requiring the static ring and the dynamic ring to have good wear resistance, the dynamic ring can move flexibly in the axial direction, and automatically compensate for the wear of the sealing surface, so that it is well fitted with the static ring; The static ring is floating and plays a cushioning role. For this reason, the sealing end face requires good processing quality to ensure good bonding performance.

2. The loading, compensation and buffering mechanism is mainly composed of elastic elements. For example: spring, push ring. The elastic element and the spring seat constitute the loading, compensation and buffer mechanism to ensure that the mechanical seal is fitted to the end face after installation; Timely compensation in case of wear; It acts as a buffer when subjected to vibration and movement.

3.auxiliary sealing ring: auxiliary sealing role, divided into compensation ring auxiliary sealing ring and non-compensation ring auxiliary sealing ring two kinds. O shape, X shape, U shape, wedge, rectangular flexible graphite, PTFE coated rubber O ring and so on.

4. connected with the rotating shaft, and coaxial rotation together with the transmission mechanism: there are: spring seat and keys or various screws. In the rotary mechanical seal, the multi-spring structure is usually driven by convex concave, pin, fork, etc. The transmission mechanism is arranged on the spring seat and compensation ring. The rotating ring is often driven by a key or pin.

5.anti-rotation mechanism: to overcome the role of torque, its structural type is opposite to the transmission structure.

In short, after we have a deep understanding of the structure of the mechanical seal, we can achieve a good sealing effect, and a stable structure is also the premise for a good sealing effect.

Post time: Jun-28-2023