What problems should be paid attention to in the selection of rubber seals

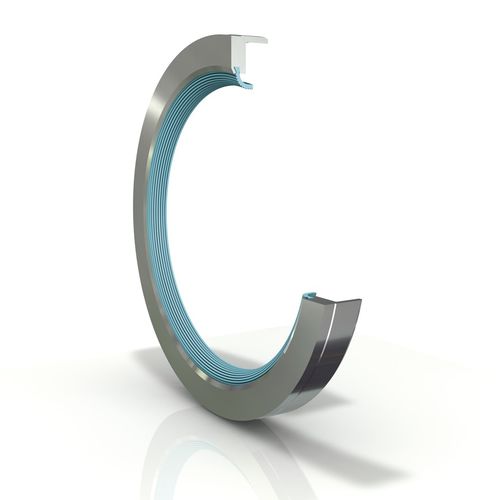

The selection of rubber seals must consider the working conditions, so as to choose the right form of seals and sealing materials, installation structure.

The selection of rubber seals needs to consider the working conditions generally include: temperature, pressure, medium. Other needs to be combined with the characteristics of the equipment itself to consider the selection of seals.

About the temperature, such as sealing material NBR material working temperature range is generally -40 ~ +120℃. It is more than 120℃ to consider the use of FKM, even PTFE material, low temperature is relatively rare, generally speaking in the case of -20 ~ -40℃ to consider the use of cold resistant NBR, NBR material in general at low temperature environment will lead to material hardening, resulting in leakage, such as railway locomotive in the north of the winter often appear such problems.

As for the pressure, it affects the form of seals to be selected. Generally speaking, the use of rubber or PU seals for low pressure and medium pressure will not have too big a problem. But to consider a problem of impact pressure, such as construction machinery in the start, close when its impact pressure is far greater than the normal working pressure, so will often choose pressure up to 70MPA impact anti-squeeze HBY or SPGW as the main seal. PTFE composite seals are also a common option.

The medium problem is simple. Just be aware of some special small problems, such as the metallurgical industry cylinder often use water-glycol and phosphate hydraulic fluids. Sometimes, although the working temperature is not high, but the selection of sealing materials should be very careful, hydraulic oil is used when the latter or FKM

The selection of seals is very important, or must be combined with the situation of the equipment itself to choose.

Post time: Jan-05-2023