I-Mechanical Face Seals DO iklanyelwe ngokuqondile izinhlelo zokusebenza ezizungezisayo ezindaweni ezinokhahlo ngokwedlulele

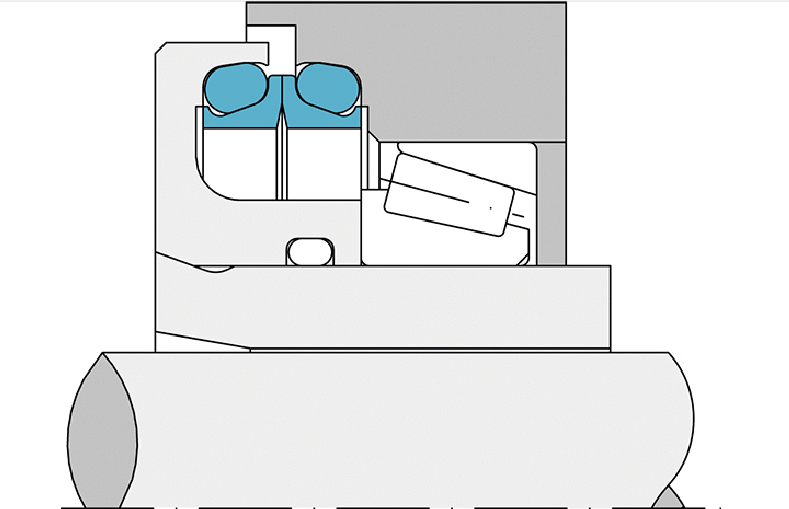

UMDWEBO WOBUCHWEPHESHE

Uhlobo lwe-DO luyifomu elivame kakhulu elisebenzisa i-O-Ringnjengento yesibili yokubeka uphawu

Uhlobo lwe-DO luqukethe izindandatho ezimbili ezifanayo zensimbi ezifakwe ezindlini ezimbili ezihlukene ezibhekene ubuso nobuso ebusweni obuboshwe uphawu.Amasongo ensimbi agxile ngaphakathi kwezindlu zawo nge-elastomer element.Ingxenye eyodwa ye-Mechanical Face Seal ihlala imile endlini, kuyilapho enye izungeza nobuso bayo bekhawunta.

I-Mechanical Face Seals isetshenziswa kakhulu ukuvala ama-bearings emishinini yokwakha noma ezimbonini zokukhiqiza ezisebenza ngaphansi kwezimo ezinzima kakhulu futhi ngaphansi kokuguga okunzima.

Lokhu kubandakanya:

Izimoto ezilandelwayo, njengama-excavators nama-bulldozer

Amasistimu okuthutha

Amaloli asindayo

Ama-ekseli

Imishini eyisicefe yomhubhe

Imishini yezolimo

Imishini yezimayini

Ama-Mechanical Face Seal afakazelwe ukuthi asetshenziswe kuma-gearbox, ama-mixers, ama-stirrer, iziteshi zikagesi eziqhutshwa umoya nezinye izinhlelo zokusebenza ezinezimo ezifanayo noma lapho kudingeka khona amazinga ancishisiwe okulungisa.

Ungasebenzisi amathuluzi acijile njenge-screwdriver ukuze ufake isigxivizo sikawoyela esintantayo, esingase kulimaze indawo yokuvala uwoyela elintantayo neringi yerabha.

Faka uphawu lwamafutha antantayo usebenzisa ithuluzi lokufaka elikhethekile.

Inqubo yokufaka i

Okokuqala gcobhoza utshwala obuncane bese usula imbobo yesihlalo esikhweleyo ukuze uyigcine ihlanzekile.Ngaphambi kokufaka isicupho senjoloba eringini yophawu entantayo, sula indandatho yerabha, indawo yokuvala yendandatho entantayo yophawu kanye nendawo yokuxhumana yeringi yenjoloba ngotshwala ukuze uvimbele uthuli ukuthi lungangeni.Bese ubeka isicupho senjoloba eringini yokuvala entantayo bese ubheka ukuthi iringi yerabha isontekile futhi ikhubazekile yini emugqeni wokuvala.Ngemuva kokuqinisekisa ukuthi umugqa wokubopha ujwayelekile, ungasebenzisa ithuluzi lokufaka ukubopha uphawu lwamafutha antantayo bese ulubeka endaweni yokufaka isihlalo.Uhlangothi lwendandatho yerabha luthinta indawo yokuhlala kuqala bese lucindezela phansi.Okokugcina, hlola ukuthi uphawu lwamafutha antantayo luvundlile yini ngemva kokulayisha, futhi indawo yazo zombili izinhlangothi nendawo yokuhlala inobude obufanayo.Amaphuzu ama-4 kuye kwayi-6 angabonwa ngokobukhulu bendandatho.Ngemva kokuqeda lezi zinyathelo ezingenhla, yonke inqubo yokufaka uphawu lwamafutha antantayo luyaqedwa.

Izinyathelo zokuphepha ngesikhathi sokufakwa:

1. Indandatho yophawu entantayo kulula ukuwohloka lapho ibekwe emoyeni isikhathi eside, ngakho uphawu oluntantayo luyasuswa lapho lufakiwe.I-float seal intekenteke kakhulu futhi kufanele iphathwe ngokucophelela.Indawo yokufaka kumele ingabi nenhlabathi nothuli.

2. Uyelulekwa ukuthi usebenzise ithuluzi lokufaka lapho ufaka uphawu lwamafutha antantayo endaweni yokuhlala.Kuvamile ukuthi i-O-ring isonteke eringini yophawu entantayo, okuholela ekucindezelekeni okungalingani kwendawo kanye nokwehluleka ngaphambi kwesikhathi, noma i-O-ring ingaphushwa iye esisekelweni bese iwe, okuholela ekuvuzeni kukawoyela ohlelweni lokuvala.

3. Izigxivizo ezintantayo zithathwa njengezingxenye ezinembayo (ikakhulukazi ingaphezulu likawoyela ovala uphawu), ngakho-ke ungasebenzisi amathuluzi abukhali ukuze udale umonakalo ezimpahleni zikawoyela ezintantayo.Ububanzi bendawo yokubopha bubukhali kakhulu.Gqoka amagilavu uma uhamba.

"Ukuvalwa kophawu lwamafutha antantayo kugcinwa ifilimu kawoyela elincanyana kakhulu elikhiqizwe phakathi kwezindawo ezithintana naye, ngakho-ke kuyadingeka ukusebenzisa uwoyela wokugcoba esigxivizweni samafutha antantayo. Kodwa-ke, izinhlobo noma izindlela zikawoyela wokugcoba ezingafanele zizodala ukusabela okuhambisana namakhemikhali. phakathi kweringi yenjoloba namafutha, okuholela ekumineni okuntantayo."

Ukuvalwa kophawu lwamafutha antantayo kugcinwa ifilimu kawoyela elincanyana kakhulu elakhiwe phakathi kwezindawo ezithintana naye, ngakho-ke kuyadingeka ukusebenzisa uwoyela wokugcoba ku-oyela elintantayo.Kodwa-ke, uhlobo olungalungile noma indlela yokugcoba uwoyela izodala ukuhambisana kwamakhemikhali phakathi kweringi yenjoloba namafutha, okuholela ekuhlulekeni kwangaphambi kwesikhathi kophawu oluntantayo.Amanye amagrisi angasetshenziswa kwezinye izimo zejubane eliphansi nokudlidliza okuphansi, kodwa uwoyela wokwenziwa owuketshezi kusafanele usetshenziswe njenge **.Ukuze ugcobe futhi upholise uphawu lwamafutha antantayo kahle, amafutha okugcoba kufanele amboze i-2/3 yendawo yokuvala.Zama ukuqinisekisa ukuhlanzeka kwamafutha kanye nesistimu yokuvala ukuze uvimbele ukulahleka kokuphila kophawu lwamafutha antantayo.Amanye amafutha awahambisani nerabha yokwenziwa, ikakhulukazi ngaphansi kwezimo zokushisa eziphakeme, futhi ukuthintana isikhathi eside kuzoholela ekugugeni.Ngakho-ke, ukuhlolwa kokuhambisana kufanele kwenziwe phakathi kwamasongo enjoloba nemikhiqizo kawoyela ngaphambi kokujova uwoyela.

Isici sawoyela esintantayo siyingxenye ebalulekile ohlelweni lokuvala lwemishini eyimishini.Uma iphutha lokuvuza litholakala ngesikhathi sokusetshenziswa, kufanele lihlolwe ngesikhathi ukuze kutholwe imbangela yephutha futhi kuxazululwe inkinga, ukuze kungathinti ukusetshenziswa okuvamile kwemishini.Okulandelayo ngabakhiqizi bezimpawu zikawoyela ezintantayo ngokweminyaka yokuhlaziywa kophawu lwamafutha antantayo kanye nokuxazulula izinkinga zokuvuza kophawu lwamafutha antantayo nezisombululo.

Iphutha imbangela eyodwa: Indawo yophawu oluntantayo ayijwayelekile

Isixazululo: Lungisa isikulufu somkhawulo se-actuator njengegiya lezikelemu noma i-actuator kagesi ukuze ivalvu ivale ngendlela efanele.

Iphutha imbangela yesibili: Kukhona umzimba wangaphandle phakathi kophawu oluntantayo nophawu

Isixazululo: Susa ukungcola ngesikhathi bese uhlanza imbobo yevalvu.

Iphutha lesithathu: Indlela yokuhlola ingcindezi ayilungile, ayihambisani nezidingo

Isixazululo: Spina ngendlela efanele lapho uya khona umcibisholo.

Ukwehluleka imbangela yesine: ibhawudi le-flange elifakwe endaweni yokuphuma licindezelwa ngokungalingani noma alicindezelwe

Isixazululo: Hlola indiza ekhwezayo namandla okucindezela amabhawudi, bese ucindezela ngokulinganayo.

Iphutha liyimbangela yesihlanu: indandatho entantayo yokuvala ukwehluleka kwe-gasket ephezulu naphansi

Isixazululo: Khipha indandatho yokucindezela yevalvu, buyisela iringi yokuvala kanye ne-gasket ehlulekile.

I-DoubleActing

Helix

Ukunyakazisa

Ukuphindisela

I-Rotary

I-SingleActing

I-Static

| Iwolintshi | Ibanga Lokucindezela | Ububanzi beTemp | Isivinini |

| 0-800 mm | 0.03Mpa | -55°C- +200°C | 3m/s |