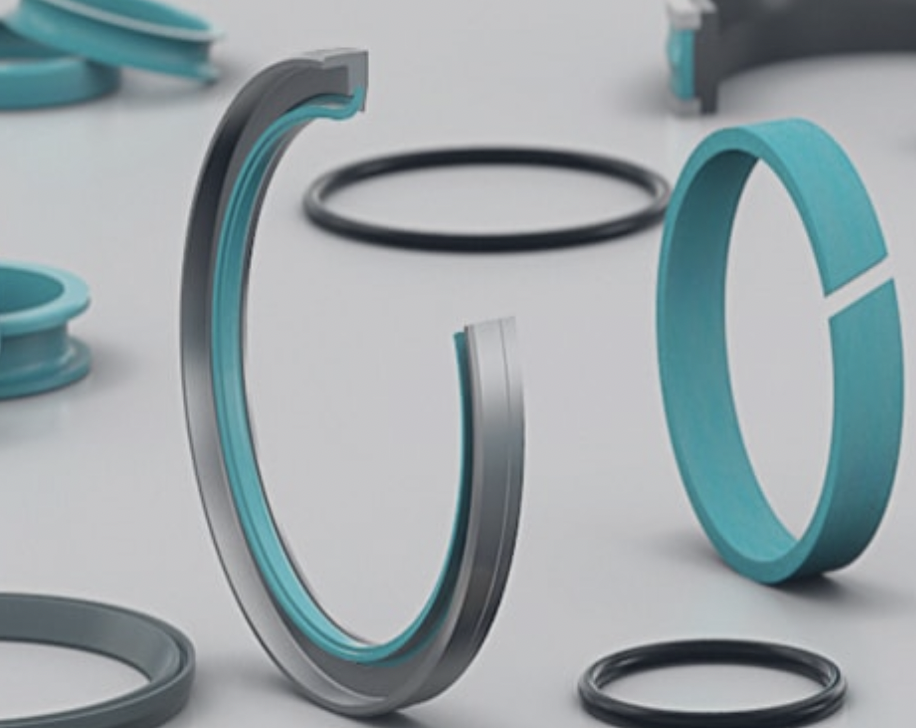

Iningi lokuphuka kwe-O-ring kwenzeka kuma-seal agqine.Ama-O-rings awuhlobo lwe-surface rubber seal ene-cross-section eyindilinga, isigaba esiphambanayo sinesimo se-O, ngakho-ke sibizwa ngokuthi i-O-ring, uphawu olusetshenziswa kakhulu ezinhlelweni zokuvala i-hydraulic kanye ne-pneumatic.Lapho impahla yophawu i-brittle, noma kunjalo, akukho ukunamathela ngokuqinile ekucacisweni kwe-welding kanye nokwelashwa kokushisa, imifantu yokucindezeleka ingenzeka kalula.Noma ukukhethwa kwempahla engafanele kanye namafomu esakhiwo angakhelwanga ukuhlangabezana nezinga lokushisa lesistimu nokucindezela kungase kubangele izenzakalo zokuphuka.Ngesikhathi sokusetshenziswa, indawo yokubeka uphawu nayo ijwayele ukuqhekeka izinto ezifana ne-hydrogen embrittlement.

Ngakho ingabe ama-O-ring fractures asalungiswa?Impendulo ecacile inguyebo, okokuqala, kufanele sisuse ngokucophelela imifantu, ngisho nokuqhekeka okuncane kufanele kucace futhi kuhlanzeke, kuqonde ngqo i-gloss yomzimba, akukho sici kuze kube manje.Impahla enothuli eyeqile kufanele isuswe, ifakwe kahle ngenduku yokushisela yepulasitiki bese inqunywa ibe yinqwaba ukuyivikela.Uma ukuthambekela kokuqhekeka kwe-weld enqwabelene yesigaba sempahla, ungqimba olungezansi lwe-weld olunqwabelene lisebenzisa ungqimba lwepulasitiki oluhle lwesendlalelo soguquko, lungavimbela ungqimba olungaphezulu lokuqhekeka.I-weld kufanele ibe mfushane ngangokunokwenzeka ukuze kuncishiswe indawo ethintekile ekushiseni futhi kuvimbele ukuwohloka kwendawo yokubeka uphawu (seal).Ngaphambi kwe-cladding weld ukuze ushise, emva kokupholisa kwe-welding ukupholisa kancane, ukuvikela ukuvimbela umoya ehholo, ukuvikela indawo yokubeka uphawu.Ngemva kokupholisa kancane, bese ucutshungulwa futhi ukwakheka.

I-ammonia iyigesi evikelayo engamuncwe yinsimbi nocingo, futhi insimbi nengxubevange ocingweni akushanelwa.Indawo ethintekile ekushiseni incane futhi ayibangeli i-slag ne-porosity kungqimba lokumbondelana, futhi ukuguqulwa kuncane.Welding umlomo wombhobho kanye sealing surface ukuze silondoloze engeli emikhulu noma mpo, ukuze ikhambi njalo ibekwe ngaphansi ukuvikelwa igesi igremu, isibhamu Welding ukwenza jika okuthile, feed wire kufanele kube umfaniswano.Ekupheleni kokugcwalisa okungaphezulu, ucingo lwe-welding oluthe xaxa kufanele lwengezwe.Bese udonsa kancane futhi uvikele isibhamu ngenkathi uphakamisa, ngemva kokuba ichibi elincibilikisiwe libanda kancane, yeka ukuphakela igesi ukuze uqedele ukulungisa.

Isikhathi sokuthumela: Mar-28-2023